WHAT IS IT?

Revamping of production plants is a type of mainentance that goes more into detail, substituting one or more parts of the plant.

It’s about updating, partially or totally, the electric/electronic part of the plant, also including mechanical improvements when needed. Issues and problems can occur, due to normal use over time, or simply there’s the need of updating the existing technology.

A revamping service is therefore a revision of the plant, with a change of components and an extraordinary maintenance.

WHY SHOULD YOU CONSIDER INVESTING IN IT?

- It extends the life of the plant up to 15/20 years;

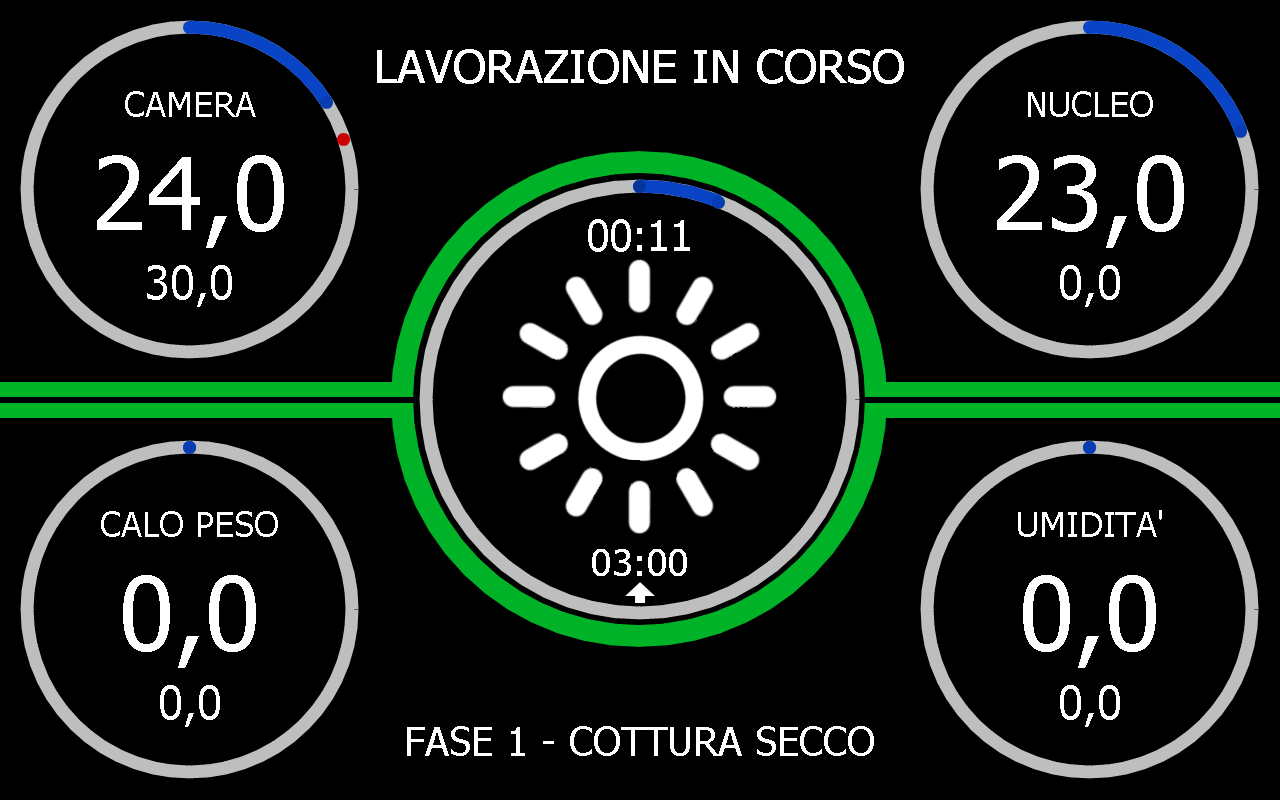

- To update the plant, with a touch-screen operating panel (HMI), allowing remote assistance and data storage (thanks to a SCADA);

- To increase safety;

- To improve quality and flexibility in the production process;

- To decrease production costs.

BEFORE

Let’s consider the case of a revamping service that has been done for a client.

At the moment of the first inspection, there was a cooking oven with a quite outdated electric control panel.

This was causing various difficulties in working and also in finding spare parts.

After the revamping service, the oven could:

- create and execute cooking recipes with temperature regulations;

- manage cooking times, based on reaching a certain temperature inside the product (core temperature);

- have all the features and functions that can be expected from a modern plant.

This translates in the automation of the cooking process, which before was completely manual.

The result was a significant waste reduction, considering time and economic investments.

AFTER

WHAT YOU CAN GET

- Connection with a SCADA supervisor;

- Remote control, with easy access to your plant’s data;

- In-plant and remote programs management;

- Production lots management;

- Integration with your internal management software;

- Conformity reports generation;

- Alarms (sms or email) in case of malfunctions.