THE COMFORT OF WIRELESS

BTW Novabase probes are studied to help companies optimizing their internal processes, without being an additional load.

They are battery-powered, can resist really high temperatures and send data via a Bluetooth mesh 5.0 networking, which can be expanded to cover quite extended areas.

These probes can follow the products during the entire supply chain: they can withstand temperatures from -35°C to+125°C (-31°F to +257°F). Thanks to this, they have no difficulty in going into the ovens or into cold storage rooms.

They are the perfect solution for process monitoring, without inconvenience or wiring, even when AGV systems are employed.

DIGITAL PROBES RELIABILITY

We are aware that accuracy is fundamental in monitoring systems. Quality relies on correct production settings and a right temperature value is one of these.

For this reason, we use digital sensors that have accuracy and precision among their strenghts: accuracy of 0,05°C (32,09°F) and precision until 0,1°C (32,18°F).

Moreover, thanks to the internal datalogger, no data gets lost, even in areas that are impossible to reach with the Bluetooth networking. The integration of real-time data and datalogger data is managed automatically by the visualization software.

AUTOMATION TECHNOLOGY

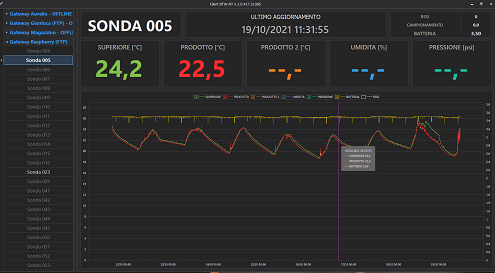

BTW probes are born to make process automation as easy as possible. This is why they send data real-time to a specific management software, which allows data reading in charts and custom historicization.

We have also developed a mobile app, to make probes’ use as dataloggers easier and user-friendly. Moreover, BTW probes are designed to be ready for M2M communication: just to mention an example among many others, they can interact with the oven and control the cooking process from the inside.

Harsh environment

wide temperature range: -35°C to +125°C (-31°F to +257°F) and IP67 rating

Precision

accuracy of 0,05°C (32,09°F) and precision until 0,1°C (32,18°F)

Wireless

this monitoring system allows automation and production speed improvement

Reliability

data logging and real-time monitoring; no data is lost

Safety

data are protected with a high-grade encryption

Long lasting

more than 6 months with a 10-seconds data transmission; more than 1 year in normal use conditions

Ease of use

data transmission from the probe to the management system is completely automatic

Minimal maintenance

the only maintenance consists in a periodic battery substitution when needed